Grinding Media

High-Chrome Grinding Media – Precision-Engineered for Gold and Base Metal Mining

At SMPE Metals, we deliver high-performance cast high-chrome grinding media designed to meet the rigorous demands of modern mineral processing. From SAG and ball mills to ultrafine regrind circuits, our grinding balls are optimized for abrasion, corrosion, and impact resistance, helping gold, copper, and base metal operations reduce media consumption, improve throughput, and enhance metallurgical recovery.

Our Offering: Cast High-Chrome Grinding Balls

We specialize in cast high-chromium alloy grinding balls — engineered with a martensitic microstructure and carbide-rich matrix to withstand tough milling conditions. Unlike traditional forged media, high-chrome balls offer superior wear performance in gold ore and sulfide flotation circuits, with lower iron contamination and better downstream recovery.

Product Grades

-

GoldMax HC-15

Standard high-chrome alloy (~15% Cr) with balanced hardness and toughness. Ideal for secondary grinding in ball mills and most gold ore applications. -

GoldMax HC-25

Premium high-chrome (~25–30% Cr) for maximum wear and corrosion resistance in aggressive grinding environments. Recommended for high-acid slurries or mines seeking longer wear life and improved recovery.

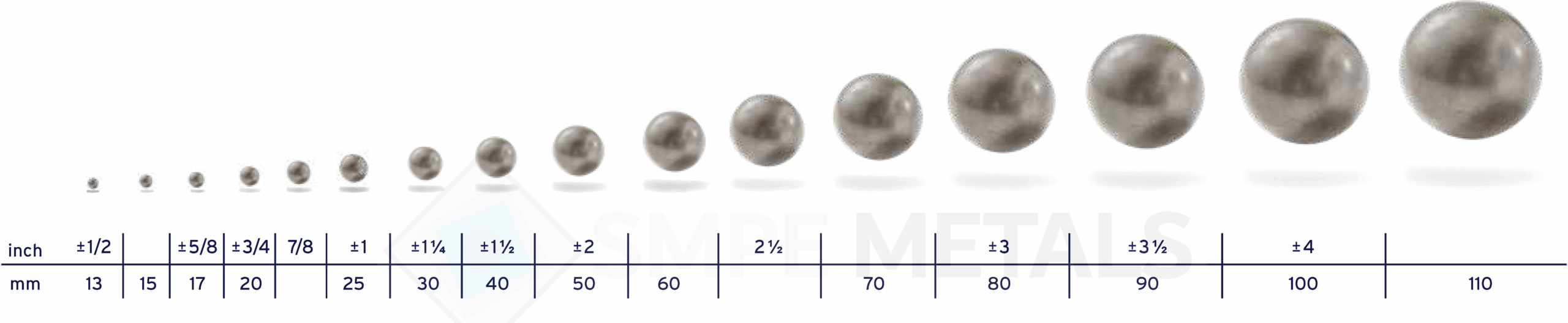

Sizes & Availability

-

Common sizes: 20 mm, 30 mm, 50 mm, 60 mm, 80 mm

-

Custom sizes on request (12 mm to 100 mm)

-

Supplied in bulk bags, drums, or containers for global shipment

-

CIF delivery to West Africa, North Africa, LATAM, and Southeast Asia

Why Choose SMPE Grinding Media

-

Consistent Hardness: 58–65 HRC through the cross-section, ensuring long-lasting performance

-

Chemically Optimized: Low impurity levels, engineered for gold and base metal ores

-

Certified Quality: ISO-compliant production, batch-level traceability, and test reports

-

Proven Performance: Designed to match or exceed the wear life of leading brands — at better value

-

Fast Delivery: Inventory available for immediate shipment to key ports (e.g. Ghana, Côte d’Ivoire, Senegal)

Technical Support & Services

We go beyond the ball. SMPE works directly with your mill and metallurgical teams to:

-

Run mill wear trials and marked ball tests

-

Provide on-site support and grinding circuit audits

-

Recommend optimal ball size distributions and charge makeups

-

Track performance and adjust alloys based on your ore conditions

Whether you’re feeding a 25,000 tpd gold mill or regrinding concentrate at 80% passing 20 microns, SMPE’s high-chrome media delivers the wear resistance and throughput your operation needs — at a total cost per ton that makes sense.

Need a Quote or Trial?

We support trial batches, offer volume pricing, and help with vendor registration for major mining groups. Contact us today to see how SMPE GoldMax HC grinding balls can reduce your media consumption and improve performance.